This paper discusses the cargo handling and storage capacity of steel structure box room in temporary port and dock facilities.

Inhoudsopgave

Advantages of Steel Structure Box Rooms in Temporary Port and Dock Facilities

Temporary port and dock facilities play a crucial role in the transportation and storage of goods and materials. These facilities are often used for short-term projects or during times of increased demand when existing ports and docks are at capacity. One key component of temporary port and dock facilities is the cargo handling and storage capacity, which can greatly impact the efficiency and effectiveness of operations.

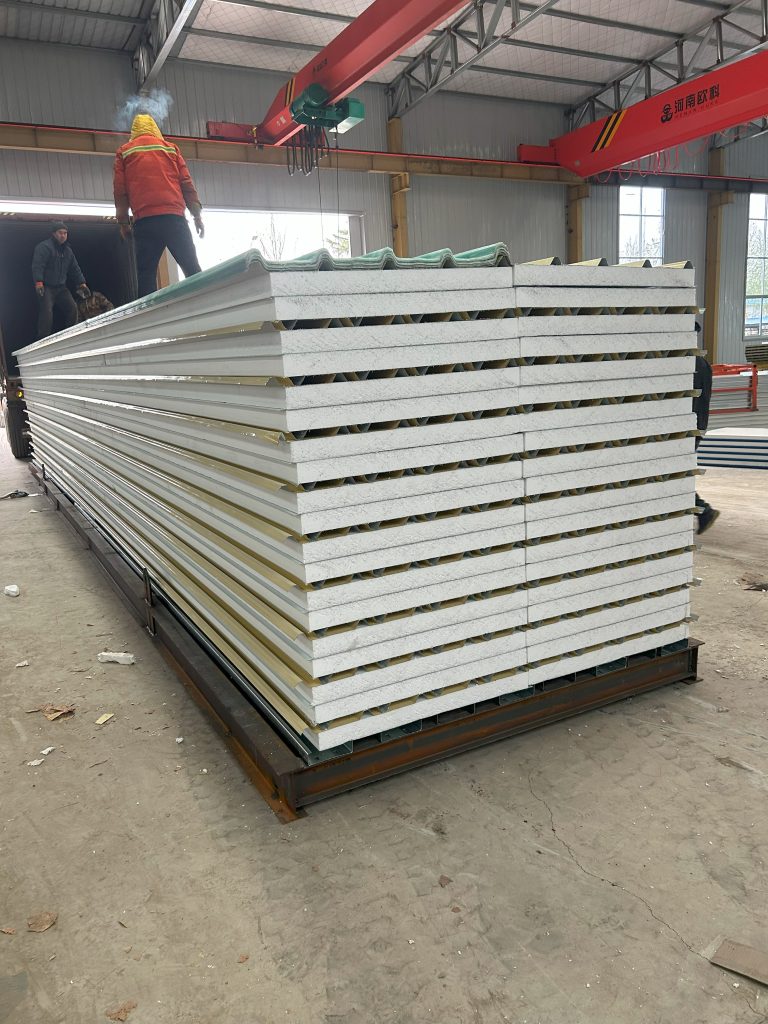

Steel structure box rooms are a popular choice for cargo handling and storage in temporary port and dock facilities due to their numerous advantages. One of the main benefits of steel structure box rooms is their durability and strength. Steel is a highly durable material that can withstand harsh weather conditions and heavy loads, making it ideal for use in port and dock facilities where goods are constantly being moved and stored.

In addition to their durability, steel structure box rooms are also highly customizable. They can be designed to fit the specific needs of the facility, whether that be for storing large equipment or handling a high volume of goods. This flexibility allows for efficient use of space and ensures that the facility can operate at maximum capacity.

Another advantage of steel structure box rooms is their ease of installation. Unlike traditional building materials, steel structures can be quickly assembled on-site, reducing construction time and costs. This is especially beneficial for temporary port and dock facilities, where time is of the essence and operations need to be up and running as soon as possible.

Furthermore, steel structure box rooms are easy to maintain and clean. Steel is a non-porous material that is resistant to mold, mildew, and pests, making it an ideal choice for storing goods and materials. Regular maintenance is minimal, and any repairs can be easily carried out without disrupting operations.

The efficiency of cargo handling and storage in temporary port and dock facilities is crucial for ensuring smooth operations and timely delivery of goods. Steel structure box rooms are designed to maximize efficiency by providing ample storage space and easy access to goods. This helps to streamline operations and reduce the risk of delays or errors in handling cargo.

In conclusion, the cargo handling and storage capacity of steel structure box rooms in temporary port and dock facilities offer numerous advantages that can greatly benefit operations. From their durability and strength to their customization and ease of installation, steel structure box rooms are a reliable and efficient choice for handling and storing goods. By investing in steel structure box rooms, temporary port and dock facilities can improve their efficiency, reduce costs, and ensure the timely delivery of goods.

Best Practices for Cargo Handling and Storage Capacity in Steel Structure Box Rooms

Temporary port and dock facilities play a crucial role in the transportation and storage of goods. One key aspect of these facilities is the cargo handling and storage capacity of steel structure box rooms. In this article, we will discuss the best practices for maximizing the efficiency and effectiveness of cargo handling and storage in steel structure box rooms.

Steel structure box rooms are commonly used in temporary port and dock facilities due to their durability and versatility. These rooms are designed to store a wide range of goods, from small packages to large containers. To ensure optimal cargo handling and storage capacity, it is important to carefully plan and organize the layout of the box rooms.

One of the key factors to consider when designing a steel structure box room is the size and layout of the room. The room should be spacious enough to accommodate the volume of goods that will be stored, while also allowing for easy access and movement of cargo. It is important to consider the dimensions of the goods that will be stored in the room, as well as the equipment that will be used for handling and transporting the goods.

In addition to size and layout, it is important to consider the organization of the goods within the box room. Goods should be stored in a systematic and organized manner to maximize the use of space and facilitate efficient handling and retrieval. This can be achieved by using shelving units, pallet racks, and other storage systems to categorize and store goods based on size, weight, and other relevant factors.

Another important aspect of cargo handling and storage in steel structure box rooms is the use of proper equipment and tools. Forklifts, pallet jacks, and other handling equipment should be readily available to facilitate the movement of goods within the room. Additionally, labeling systems and inventory management software can help track the location and status of goods in real-time, ensuring efficient handling and storage.

Proper ventilation and lighting are also essential for maintaining the quality and condition of goods stored in steel structure box rooms. Adequate ventilation helps prevent moisture buildup and mold growth, while proper lighting ensures visibility and safety for workers handling the goods. It is important to regularly inspect and maintain the ventilation and lighting systems to ensure they are functioning properly.

In conclusion, maximizing the cargo handling and storage capacity of steel structure box rooms in temporary port and dock facilities requires careful planning, organization, and utilization of resources. By considering factors such as size, layout, organization, equipment, ventilation, and lighting, facilities can optimize the efficiency and effectiveness of their cargo handling operations. Implementing these best practices will help ensure the smooth and seamless transportation and storage of goods in steel structure box rooms.